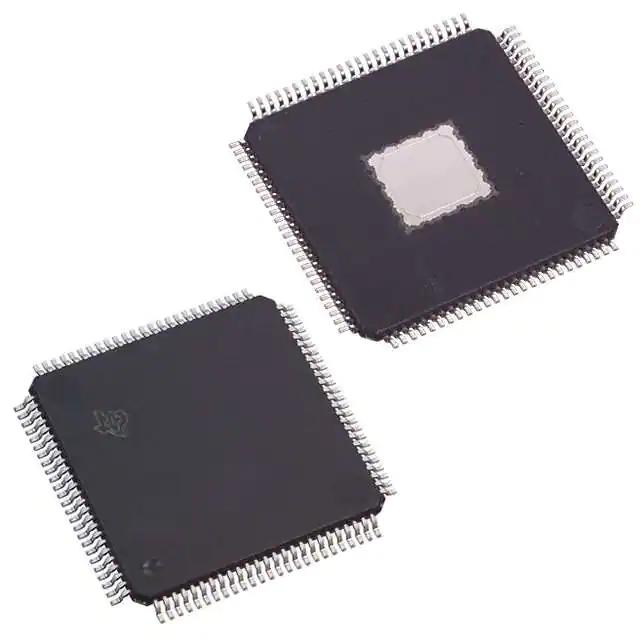

Sabbin asali na asali na IC kayan lantarki Kayan Wuta Ic Chip Support BOM Service DS90UB953TRHBRQ1

Halayen Samfur

| TYPE | BAYANI |

| Kashi | Haɗin kai (ICs) |

| Mfr | Texas Instruments |

| Jerin | Mota, AEC-Q100 |

| Kunshin | Tape & Reel (TR) Yanke Tape (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Matsayin samfur | Mai aiki |

| Aiki | Serializer |

| Adadin Bayanai | 4.16Gbps |

| Nau'in shigarwa | CSI-2, MIPI |

| Nau'in fitarwa | FPD-Link III, LVDS |

| Adadin abubuwan shigarwa | 1 |

| Adadin abubuwan da aka fitar | 1 |

| Voltage - Samfura | 1.71V ~ 1.89V |

| Yanayin Aiki | -40°C ~ 105°C |

| Nau'in hawa | Dutsen Surface, Flank Wettable |

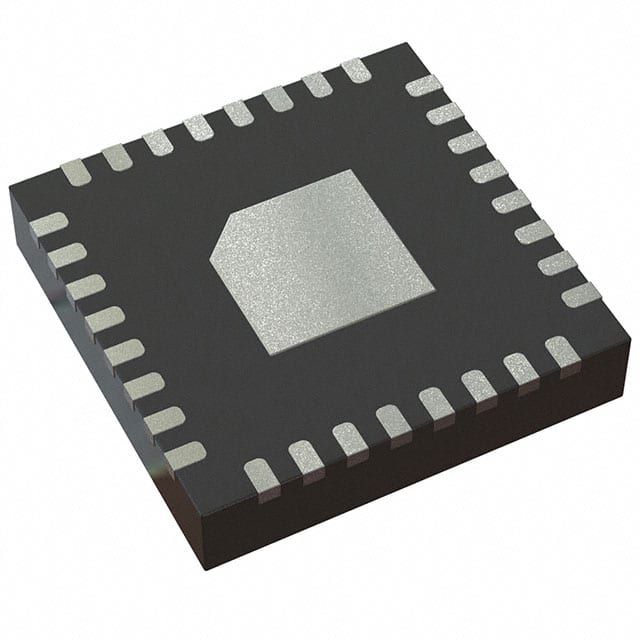

| Kunshin / Case | 32-VFQFN Fitar da Kushin |

| Kunshin Na'urar Mai bayarwa | 32-VQFN (5x5) |

| Lambar Samfurin Tushen | Saukewa: DS90UB953 |

1.Me yasa silicon don kwakwalwan kwamfuta?Shin akwai kayan da za su iya maye gurbinsa a nan gaba?

Abubuwan da ake amfani da su don kwakwalwan kwamfuta shine wafers, waɗanda suka ƙunshi silicon.Akwai kuskuren cewa "ana iya amfani da yashi don yin guntu", amma wannan ba haka bane.Babban sinadari na yashi shine silicon dioxide, kuma babban sinadari na gilashi da wafers kuma shine silicon dioxide.Bambancin, duk da haka, shine gilashin siliki na polycrystalline, kuma yashi mai zafi a yanayin zafi yana haifar da silicon polycrystalline.Wafers kuma, siliki ne na monocrystalline, kuma idan an yi su daga yashi suna buƙatar a ƙara canza su daga siliki na polycrystalline zuwa silicon monocrystalline.

Menene ainihin silicon kuma me yasa za'a iya amfani dashi don yin kwakwalwan kwamfuta, zamu bayyana wannan a cikin wannan labarin daya bayan daya.

Abu na farko da ya kamata mu fahimta shi ne cewa siliki abu ba tsalle kai tsaye zuwa guntu mataki, siliki da aka tace daga quartz yashi daga silica silica, silicon element proton lambar fiye da kashi aluminum daya more, fiye da kashi phosphorus daya kasa. , Ba wai kawai tushen kayan aikin na'urorin kwamfuta na zamani ba har ma da mutanen da ke neman rayuwar wuce gona da iri ɗaya daga cikin abubuwan da za su iya yiwuwa.Yawancin lokaci, lokacin da aka tsaftace silicon kuma an tsaftace shi (99.999%), ana iya ƙera shi a cikin wafers na silicon, sannan a yanka su cikin waƙafi.Mafi ƙarancin wafer, ƙananan farashin kera guntu, amma mafi girman buƙatun tsarin guntu.

Matakai guda uku masu mahimmanci wajen juya siliki zuwa wafers

Musamman, ana iya raba juzu'i na siliki zuwa wafers zuwa matakai uku: tsaftace siliki da tsarkakewa, haɓakar silicon crystal guda ɗaya, da ƙirƙira wafer.

A cikin yanayi, ana samun silicon gabaɗaya a cikin silicate ko silicon dioxide a cikin yashi da tsakuwa.Ana sanya danyen abu a cikin tanderun wutar lantarki a 2000 ° C kuma a gaban tushen carbon, kuma ana amfani da babban zafin jiki don amsa silicon dioxide tare da carbon (SiO2 + 2C = Si + 2CO) don samun silikon ƙarfe na ƙarfe (SiO2 + 2C = Si + 2CO). tsarki a kusa da 98%).Duk da haka, wannan tsarki bai isa ba don shirya kayan aikin lantarki, don haka dole ne a kara tsarkake shi.Silicon da aka murƙushe ƙarfe na ƙarfe yana da chlorinated tare da hydrogen chloride gaseous don samar da silane na ruwa, wanda sannan aka distilled kuma an rage shi da sinadarai ta hanyar da ke haifar da polysilicon mai tsafta tare da tsaftar 99.9999999999% azaman siliki.

Don haka ta yaya za ku sami silicon monocrystalline daga silicon polycrystalline?Hanyar da aka fi sani da ita ita ce hanyar jawo kai tsaye, inda aka sanya polysilicon a cikin ma'auni na ma'adini kuma a yi zafi tare da zafin jiki na 1400 ° C da ke kewaye da shi, wanda ke haifar da narke polysilicon.Tabbas, ana gaba da wannan ta hanyar tsoma kristal iri a ciki da kuma samun sandar zane tana ɗaukar kristal iri a kishiyar alkibla yayin da a hankali kuma a tsaye ake jan shi sama daga narkewar siliki.Narkewar siliki ta polycrystalline yana manne da kasan kristal iri kuma ya girma zuwa sama a cikin al'amuran kristal na iri, wanda bayan an cire shi kuma ya sanyaya ya girma zuwa shingen kristal guda ɗaya tare da daidaitawar lattice kamar crystal iri na ciki.A ƙarshe, wafers ɗin da aka yi da lu'u-lu'u guda ɗaya suna tumɓukewa, yanke, ƙasa, chamfered, da goge don samar da wafers masu mahimmanci.

Dangane da girman da aka yanke, za a iya rarraba wafers na siliki a matsayin 6", 8", 12, da 18".Girman girman wafer, mafi yawan kwakwalwan kwamfuta za a iya yankewa daga kowane wafer, kuma ƙananan farashin kowane guntu.

2.Three muhimman matakai a cikin canji na silicon cikin wafers

Musamman, ana iya raba juzu'i na siliki zuwa wafers zuwa matakai uku: tsaftace siliki da tsarkakewa, haɓakar silicon crystal guda ɗaya, da ƙirƙira wafer.

A cikin yanayi, ana samun silicon gabaɗaya a cikin silicate ko silicon dioxide a cikin yashi da tsakuwa.Ana sanya danyen abu a cikin tanderun wutar lantarki a 2000 ° C kuma a gaban tushen carbon, kuma ana amfani da babban zafin jiki don amsa silicon dioxide tare da carbon (SiO2 + 2C = Si + 2CO) don samun silikon ƙarfe na ƙarfe (SiO2 + 2C = Si + 2CO). tsarki kusan 98%).Duk da haka, wannan tsarki bai isa ba don shirya kayan aikin lantarki, don haka dole ne a kara tsarkake shi.Silicon da aka murƙushe ƙarfe na ƙarfe yana da chlorinated tare da hydrogen chloride gaseous don samar da silane na ruwa, wanda sannan aka distilled kuma an rage shi da sinadarai ta hanyar da ke haifar da polysilicon mai tsafta tare da tsaftar 99.9999999999% azaman siliki.

Don haka ta yaya za ku sami silicon monocrystalline daga silicon polycrystalline?Hanyar da aka fi sani da ita ita ce hanyar jawo kai tsaye, inda aka sanya polysilicon a cikin ma'auni na ma'adini kuma a yi zafi tare da zafin jiki na 1400 ° C da ke kewaye da shi, wanda ke haifar da narke polysilicon.Tabbas, ana gaba da wannan ta hanyar tsoma kristal iri a ciki da kuma samun sandar zane tana ɗaukar kristal iri a kishiyar alkibla yayin da a hankali kuma a tsaye ake jan shi sama daga narkewar siliki.Narkewar siliki ta polycrystalline yana manne da kasan kristal iri kuma ya girma zuwa sama a cikin al'amuran kristal na iri, wanda bayan an cire shi kuma ya sanyaya ya girma zuwa shingen kristal guda ɗaya tare da daidaitawar lattice kamar crystal iri na ciki.A ƙarshe, wafers ɗin da aka yi da lu'u-lu'u guda ɗaya suna tumɓukewa, yanke, ƙasa, chamfered, da goge don samar da wafers masu mahimmanci.

Dangane da girman da aka yanke, za a iya rarraba wafers na siliki a matsayin 6", 8", 12, da 18".Girman girman wafer, mafi yawan kwakwalwan kwamfuta za a iya yankewa daga kowane wafer, kuma ƙananan farashin kowane guntu.

Me yasa silicon shine mafi dacewa kayan don yin kwakwalwan kwamfuta?

A ka'ida, duk semiconductor ana iya amfani dashi azaman kayan guntu, amma manyan dalilan da yasa silicon shine mafi dacewa kayan don yin kwakwalwan kwamfuta sune kamar haka.

1, bisa ga darajar abubuwan da ke cikin ƙasa, domin: oxygen> silicon> aluminum> iron> calcium> sodium> potassium ...... na iya ganin cewa silicon ya zama na biyu, abun ciki yana da girma, wanda kuma ya ba da damar guntu don samun wadatar albarkatun ƙasa kusan mara ƙarewa.

2, Silicone element Properties and material Properties are very barga, farkon transistor shine amfani da kayan aikin semiconductor germanium don yin, amma saboda zafin jiki ya wuce 75 ℃, ƙaddamarwa zai zama babban canji, wanda aka sanya shi cikin haɗin PN bayan juyawa. Leakage halin yanzu na germanium fiye da siliki, don haka zaɓin siliki a matsayin kayan guntu ya fi dacewa;

3, fasahar tsarkakewa ta siliki ta girma, kuma ƙarancin farashi, a zamanin yau tsarkakewar silicon na iya kaiwa 99.9999999999%.

4, silicon abu da kanta ba mai guba da kuma m, wanda kuma shi ne daya daga cikin muhimman dalilan da ya sa aka zaba a matsayin masana'antu kayan don kwakwalwan kwamfuta.

.png)