LM46002AQPWPRQ1 fakitin HTSSOP16 hadedde da'ira IC guntu sabon asali tabo kayan lantarki

Halayen Samfur

| TYPE | BAYANI |

| Kashi | Haɗin kai (ICs) Gudanar da Wutar Lantarki (PMIC) Masu Gudanar da Wutar Lantarki - Masu Gudanar da Canjawar DC DC |

| Mfr | Texas Instruments |

| Jerin | Mota, AEC-Q100, SIMPLE SWITCHER® |

| Kunshin | Tape & Reel (TR) Yanke Tape (CT) Digi-Reel® |

| SPQ | 2000T&R |

| Matsayin samfur | Mai aiki |

| Aiki | Mataki-Ƙasa |

| Kanfigareshan fitarwa | M |

| Topology | Baka |

| Nau'in fitarwa | daidaitacce |

| Adadin abubuwan da aka fitar | 1 |

| Wutar lantarki - Input (min) | 3.5V |

| Wutar lantarki - Input (Max) | 60V |

| Voltage - Fitarwa (min / Kafaffen) | 1V |

| Wutar lantarki - Fitarwa (Max) | 28V |

| Yanzu - Fitowa | 2A |

| Mitar - Canjawa | 200kHz ~ 2.2MHz |

| Mai gyara aiki tare | Ee |

| Yanayin Aiki | -40°C ~ 125°C (TJ) |

| Nau'in hawa | Dutsen Surface |

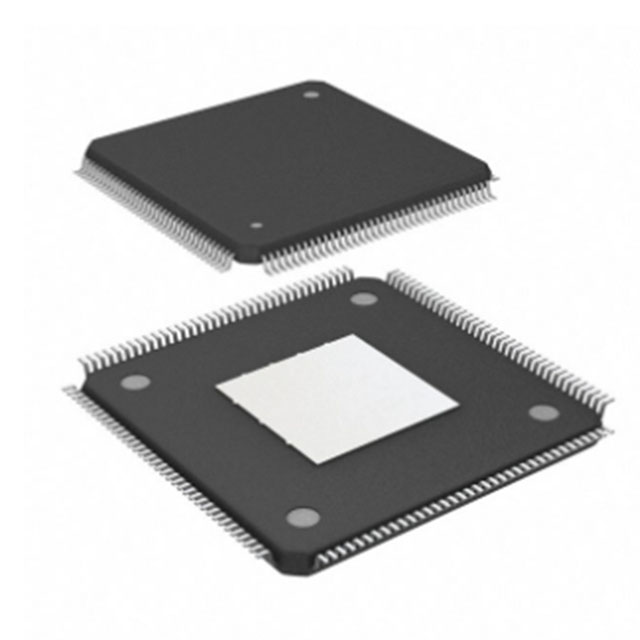

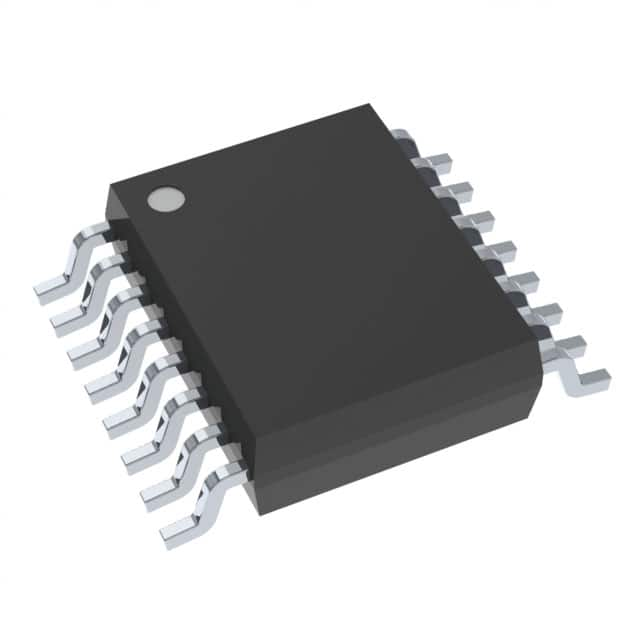

| Kunshin / Case | 16-TSSOP (0.173", Nisa 4.40mm) Faɗin Faɗakarwa |

| Kunshin Na'urar Mai bayarwa | 16-HTSSOP |

| Lambar Samfurin Tushen | Saukewa: LM46002 |

Tsarin samar da guntu

Cikakken tsarin ƙirƙira guntu ya haɗa da ƙirar guntu, samar da wafer, fakitin guntu, da gwajin guntu, waɗanda tsarin samar da wafer yana da rikitarwa musamman.

Mataki na farko shine ƙirar guntu, wanda ya dogara da buƙatun ƙira, kamar maƙasudin aiki, ƙayyadaddun ƙayyadaddun bayanai, shimfidar kewayawa, iska da bayanai dalla-dalla, da dai sauransu. An samar da "zanen zane";Ana samar da hotunan hotunan a gaba bisa ga ka'idodin guntu.

②.Wafer samarwa.

1. Ana yanke wafern siliki zuwa kauri da ake buƙata ta amfani da slicer wafer.Mafi ƙarancin wafer, ƙananan farashin samarwa, amma mafi buƙatar tsari.

2. Rufe saman wafer tare da fim ɗin photoresist, wanda ke inganta juriya na wafer ga oxidation da zafin jiki.

3. Wafer photolithography ci gaba da etching yana amfani da sinadarai masu kula da hasken UV, watau suna yin laushi lokacin da aka fallasa su ga hasken UV.Ana iya samun siffar guntu ta hanyar sarrafa matsayi na abin rufe fuska.Ana amfani da mai ɗaukar hoto a kan wafer silicon ta yadda zai narke lokacin da aka fallasa shi ga hasken UV.Ana yin hakan ne ta hanyar amfani da ɓangaren farko na abin rufe fuska domin ɓangaren da ke fallasa hasken UV ya narke kuma wannan ɓangaren narkar da za a iya wanke shi da sauran ƙarfi.Ana iya wanke wannan ɓangaren da aka narkar da shi da sauran ƙarfi.Saura bangaren kuma ana siffanta su kamar photoresist, yana ba mu siliki da ake so.

4. allurar ions.Yin amfani da na'urar etching, tarkon N da P ana saka su a cikin siliki mara kyau, kuma ana allurar ions don samar da hanyar haɗin PN (ƙofar dabaru);Sa'an nan kuma an haɗa Layer na ƙarfe na sama zuwa kewaye ta hanyar sinadarai da hazo na jiki.

5. Gwajin wafer Bayan matakan da ke sama, an kafa lattice na dice akan wafer.Ana gwada halayen lantarki na kowane mutu ta amfani da gwajin fil.

③.Chip marufi

An gyara wafer ɗin da aka gama, an ɗaure shi zuwa fil, kuma an sanya shi cikin fakiti daban-daban bisa ga buƙata.Misalai: DIP, QFP, PLCC, QFN, da sauransu.An ƙayyade wannan musamman ta dabi'un aikace-aikacen mai amfani, yanayin aikace-aikacen, yanayin kasuwa, da sauran abubuwan da ke kewaye.

④.Gwajin guntu

A karshe tsari na guntu masana'antu ne gama samfurin gwajin, wanda za a iya raba general gwaji da gwaji na musamman, tsohon shi ne don gwada lantarki halaye na guntu bayan marufi a daban-daban yanayi, kamar ikon amfani, aiki gudun, ƙarfin lantarki juriya, da sauransu. Bayan gwaji, ana rarraba kwakwalwan kwamfuta zuwa maki daban-daban gwargwadon halayen lantarki.Gwajin na musamman ya dogara ne akan sigogin fasaha na bukatun musamman na abokin ciniki, kuma ana gwada wasu kwakwalwan kwamfuta daga nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan don ganin ko za su iya biyan buƙatun abokin ciniki, don yanke shawarar ko yakamata a tsara guntu na musamman don abokin ciniki.Kayayyakin da suka ci jarrabawar gabaɗaya ana yi musu lakabi da ƙayyadaddun bayanai, lambobin ƙira, da kwanakin masana'anta da kuma kunshe su kafin barin masana'anta.Chips waɗanda ba su ci gwajin ba ana rarraba su azaman waɗanda aka rage ko ƙi su dangane da sigogin da suka samu.

.png)