Abubuwan Kayan Wutar Lantarki na Semiconductors TPS7A5201QRGRRQ1 Ic Chips BOM sabis tabo daya saya

Halayen Samfur

| TYPE | BAYANI |

| Kashi | Haɗin kai (ICs) |

| Mfr | Texas Instruments |

| Jerin | Mota, AEC-Q100 |

| Kunshin | Tape & Reel (TR) Yanke Tape (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Matsayin samfur | Mai aiki |

| Kanfigareshan fitarwa | M |

| Nau'in fitarwa | daidaitacce |

| Adadin Masu Gudanarwa | 1 |

| Wutar lantarki - Input (Max) | 6.5V |

| Voltage - Fitarwa (min / Kafaffen) | 0.8V |

| Wutar lantarki - Fitarwa (Max) | 5.2V |

| Fitar da wutar lantarki (Max) | 0.3V @ 2A |

| Yanzu - Fitowa | 2A |

| PSRR | 42dB ~ 25dB (10kHz ~ 500kHz) |

| Siffofin sarrafawa | Kunna |

| Siffofin Kariya | Sama da Zazzabi, Juya Polarity |

| Yanayin Aiki | -40°C ~ 150°C (TJ) |

| Nau'in hawa | Dutsen Surface |

| Kunshin / Case | 20-VFQFN Fitar da Kushin |

| Kunshin Na'urar Mai bayarwa | 20-VQFN (3.5x3.5) |

| Lambar Samfurin Tushen | Saukewa: TPS7A5201 |

Bayanin kwakwalwan kwamfuta

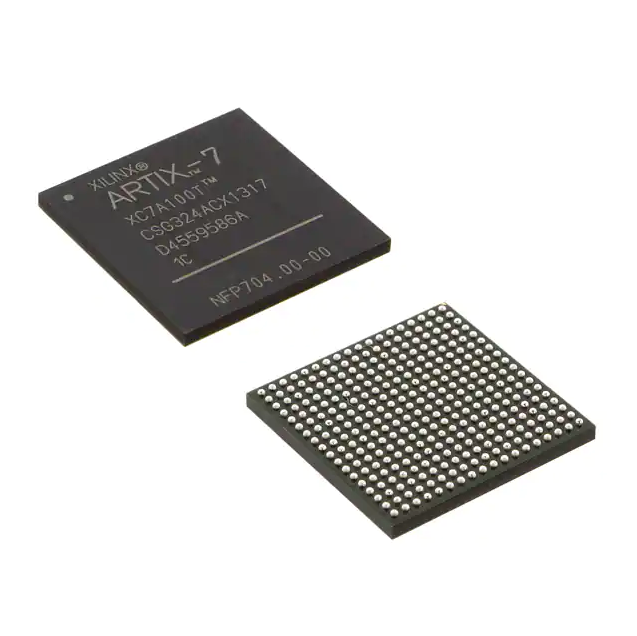

(i) Menene guntu

Da'irar da aka haɗa, wanda aka rage a matsayin IC;ko microcircuit, microchip, guntu wata hanya ce ta rage da'irori (yafi na'urorin semiconductor, amma kuma abubuwan da ba a iya amfani da su, da sauransu) a cikin kayan lantarki, kuma galibi ana kera su akan saman wafers na semiconductor.

(ii) Tsarin sarrafa guntu

Cikakken tsarin ƙirar guntu ya haɗa da ƙirar guntu, ƙirƙira wafer, ƙirƙira fakiti, da gwaji, daga cikin abin da ƙirar wafer ɗin ke da rikitarwa musamman.

Na farko shine ƙirar guntu, bisa ga buƙatun ƙira, “samfurin” da aka samar, albarkatun ƙasa na guntu shine wafer.

Wafer an yi shi da siliki, wanda aka tace daga yashi quartz.Wafer shine sinadarin silicon da aka tsarkake (99.999%), sannan ana yin siliki mai tsabta a cikin sandunan siliki, wanda ya zama kayan aikin masana'anta na ma'adini na ma'auni don haɗaɗɗun da'irori, waɗanda aka yanka a cikin wafers don samar da guntu.Mafi ƙarancin wafer, ƙananan farashin samarwa, amma mafi buƙatar tsari.

Wafer shafi

Rufin wafer yana da tsayayya da iskar shaka da juriya na zafin jiki kuma shine nau'in photoresisist.

Wafer photolithography ci gaba da etching

Ana nuna ainihin kwararar tsarin photolithography a cikin zanen da ke ƙasa.Da farko, ana amfani da Layer na photoresist a saman wafer (ko substrate) kuma a bushe.Bayan bushewa, ana canza wafer zuwa injin lithography.Ana wuce haske ta hanyar abin rufe fuska don aiwatar da tsari akan abin rufe fuska akan mai ɗaukar hoto akan farfajiyar wafer, yana ba da damar bayyanawa da haɓaka halayen photochemical.Ana gasa wafers ɗin da aka fallasa a karo na biyu, wanda aka sani da yin burodi bayan fallasa, inda halayen photochemical ya fi cikakke.A ƙarshe, ana fesa mai haɓakawa akan photoresist akan farfajiyar wafer don haɓaka ƙirar da aka fallasa.Bayan ci gaba, an bar samfurin a kan abin rufe fuska a kan photoresisist.

Ana yin manne, yin burodi, da haɓakawa duk ana yin su a cikin mai haɓakawa kuma ana yin fallasa a cikin hoto.Mai haɓakawa da injin lithography gabaɗaya ana sarrafa su ta layi, tare da canja wurin wafers tsakanin raka'a da injin ta amfani da robot.An rufe dukkan tsarin bayyanarwa da ci gaba kuma ba a bayyana wafers kai tsaye zuwa yanayin da ke kewaye da su don rage tasirin abubuwan da ke da lahani a cikin yanayi akan halayen photoresisist da photochemical.

Doping tare da ƙazanta

Dasa ions a cikin wafer don samar da daidaitattun na'urori masu kama da nau'in P da N.

Gwajin wafer

Bayan matakan da ke sama, an kafa lattice na dice akan wafer.Ana duba halayen lantarki na kowane mutu ta amfani da gwajin fil.

Marufi

Wafers ɗin da aka ƙera an gyara su, an ɗaure su da fil, kuma an sanya su cikin fakiti daban-daban bisa ga buƙatun, wanda shine dalilin da yasa za'a iya haɗa tushen guntu iri ɗaya ta hanyoyi daban-daban.Misali, DIP, QFP, PLCC, QFN, da sauransu.Anan an ƙayyade shi ta hanyar halayen aikace-aikacen mai amfani, yanayin aikace-aikacen, tsarin kasuwa, da sauran abubuwan da ke kewaye.

Gwaji, marufi

Bayan tsarin da ke sama, aikin guntu ya cika.Wannan mataki shine don gwada guntu, cire samfuran da ba su da lahani kuma a haɗa shi.

Dangantaka tsakanin wafers da kwakwalwan kwamfuta

Guntu yana ƙunshe da na'urar semiconductor fiye da ɗaya.Semiconductor gabaɗaya diodes, triodes, bututun tasirin filin, ƙananan ƙarfin wuta, inductor, capacitors, da sauransu.

Yin amfani da hanyoyin fasaha ne don canza ma'auni na electrons kyauta a cikin tsakiya na atomic a cikin rijiyar madauwari don canza halayen jiki na kwayoyin halitta don samar da caji mai kyau ko mara kyau na yawancin (electrons) ko 'yan (ramuka) zuwa. samar da daban-daban semiconductors.

Silicon da germanium ana yawan amfani da kayan semiconductor kuma kaddarorinsu da kayansu ana samunsu da yawa a farashi mai rahusa don amfani da waɗannan fasahohin.

Wafer siliki an yi shi da ɗimbin na'urorin semiconductor.Ayyukan semiconductor shine, ba shakka, don samar da kewayawa kamar yadda ake buƙata kuma ya kasance a cikin wafer silicon.